compressor engine starts but runs rough.(GAS ENGINE)

There are several reasons an engine will start but will run rough, The most common reason small gas engine run rough is poor fuel Quality.

The first recommended test Is to pull a small sample of fuel in a clear glass let is sit and see if it separates there will be a noticeable layer of water or oil is present, if the fuel smells bad or has noticeable contamination clean the tank, spark plugs fuel lines and replace the fuel filter.

If the fuel looks good remove the spark plug and check for a strong spark, The Spark should be white/blue not yellow. If The Spark is yellow clean or replace the plug making sure it is gapped correctly according to the engine manufactures spec.

clean the carburetor with carb-cleaner replace the fuel filter and retest engine.

If the engine is hard to start and everything so far checks out. there is a slight possibility that the crankshaft keyway is split or broken. The keyway keeps the flywheel in line with the crank if it off the engine will be out of time and will be hard to start and or run rough.

DONYBOY73 Compressor Engine cranks but will not start. (GAS ENGINE)

The most common cause of a small engine not starting is a lack of spark. Test the coil for spark before moving on remove the coil wire from the top of the spark plug insert a Philips head screwdriver into the coil wire hold the metal shank of the screwdriver to the head holding no more than 1/16 of an inch away making sure not to come in contact with the metal, crank the engine you should observe a spark jump from the screwdriver to the head, To check the sparkplug remove the sparkplug from the cylinder head. Attach the coil wire onto the top of the spark plug. hold the bottom of the spark plug to the top of the head. crank over the engine and inspect to see if the plug has a hot white/blue spark.

If the spark is weak clean or replace it making sure to properly gap the plug, perform spark test again if it looks good reinstall it in to the cylinder head and start the engine.

Air compressor engine Has spark but wont start.

At this point there are three reasons an engine wont start If It has good Spark,

- No fuel or very poor fuel

- The engine has spark and fuel but the timing is so far off that fuel and spark don’t get introduced to each other.( this is very unusual the crank key would have to be sheered flywheel would have to be off 180 degrees.)

- No compression.

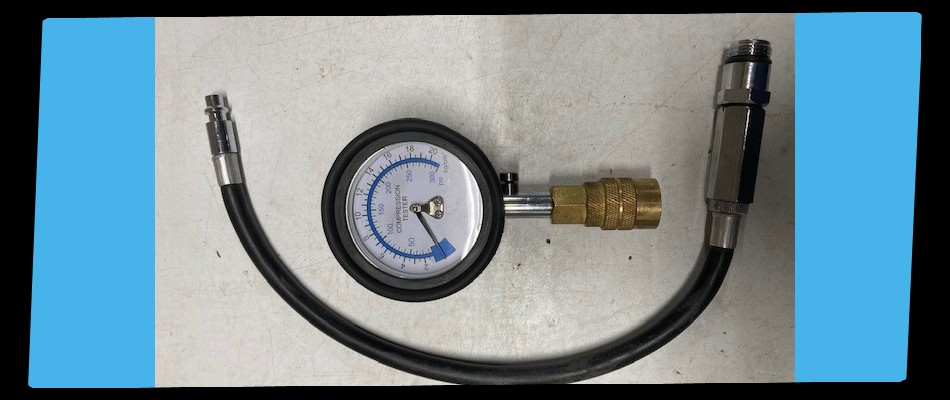

How to Test Compression on an air compressor engine.

Remove the spark plug, Install a compression gauge into the cylinder head. Remove the air filter to expose the butterfly in the carburetor take a screwdriver insert it into the carburetor valve body to hold open the butterfly, crank over the engine until the needle stops rising you should have at least 60psi factory would be 80 to 90psi. let it sit the pressure should hold for 3 to 5 min. pull the pressure gauge put a table spoon of 10w30 oil in the cylinder reinstall the compression gauge. Crank over the Engine until the needle stops rising The gauge should read the same. if the gauge goes up 2 to 5psi the rings maybe getting worn if the pressure goes up more than that the valves are letting pressure past. one note the pressure should last longer in the cylinder head while wet testing with oil.