Just as with other workshop tools, it is always challenging and difficult to decide which air compressor to choose, The fact that there are a number of factors to consider such as duration of operation, maximum pressure, expected lifespan of the compressor, and the type to choose. Among the important consideration to make is choosing between a single and two-stage compressor. Here, you are going to learn about the differences between these types of portable air compressors.

| Check this article out if you have a problem with Your Air compressor Troubleshooting a gas-powered air compressor that won’s start |

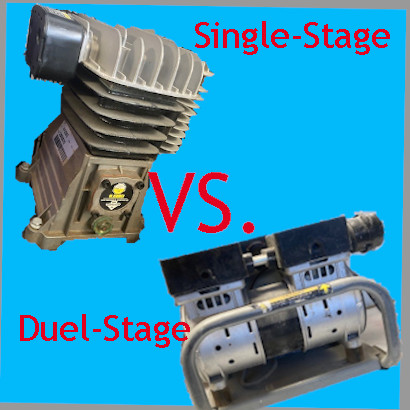

the difference between a Single and Two-Stage Air Compressor

The major difference between these two types of air compressors as their name already tells you is the number of times their air is compressed. The air is compressed once in a single or one-stage air compressor but in a two or dual-stage system, the air is compressed two times. Air is pushed into the cylinder but in a single-stage compressor, it is compressed to a pressure of approximately 120 PSI in a single-piston stoke before it is moved into the air storage chamber of the device.

The process at the initial stage is the same in the Multi-stage or two-stage air compressor. But after the initial piston stoke, The air is not sent to the storage chamber directly. It moves through an intercooler to another smaller high-pressure piston for further compression to The final pressure. It is after this second compression that the compressed air is sent to the storage chamber. This major difference in the process through which air is compressed matters a lot as it introduces other differences.

multi-stage compressor are more efficient, The cylinders can reach higher pressure with only slighter higher energy use, resulting in more cubic feet stored in the same space. using more stages, I Have worked on 3 and 4 stage compressors that reach up to 6000psi I believe the most common of these are compressors used to fill cylinders for paint ball guns.

The single-stage piston and dual-stage compressor are slightly different in their structural designs. You can differentiate them by the look of their cylinders. Most single-stage compressors have two cylinders like dual-stage air compressors. But the designs of these cylinders are not the same. In a single-stage air compressor, the outside diameter of the two cylinders is the same while in a dual-stage air compressor, one of the cylinders is larger than the other. The larger one is the first stage cylinder. The reason why a single-stage cylinder comes with double cylinders is that it makes it easier for the device to balance than when it comes with a single cylinder.

Structurally also, the two stage air compressor has a finned housing or inter cooler tube which cools the air before the second compression takes place. It is attached to the pump.

The dual stage air compressor stores more compressed air because it has higher pressure which makes for enhanced storage of air in the chamber. For example, a tank of 80 gallon capacity can hold 83 cubic feet at 100 PSI. But at 150 psi, the same tank can also contain 120 cubic feet.

The header pipe pressure maintained by a two stage compressor is higher than the header pipe pressure maintained by a single stage compressor. The dual stage air compressor can maintain a header pipe pressure of 125 psi while the single stage compressor will only maintain a 90 psi header pipe pressure. Owing to this difference, dual stage air compressor are suitable for heavy task while single stage air compressors are suitable for light tasks.