I work with and on many types of air compressors. Years ago, the medical field, scuba diving, and air exchange like mine shafts and sewer systems would be the only oil-free compressors to be found. Oil-free became oil-less Air Compressors and started popping up for home use. The advantage mainly was fewer parts and more compact resulting in a lower affordable cost. Unfortunately, they were garbage! Homeowners may get a few years of use from an oil-less compressor but avoid using it because it was so loud. Professionals hated them. They didn’t last, It would shake across the floor, and the noise was unbearable.

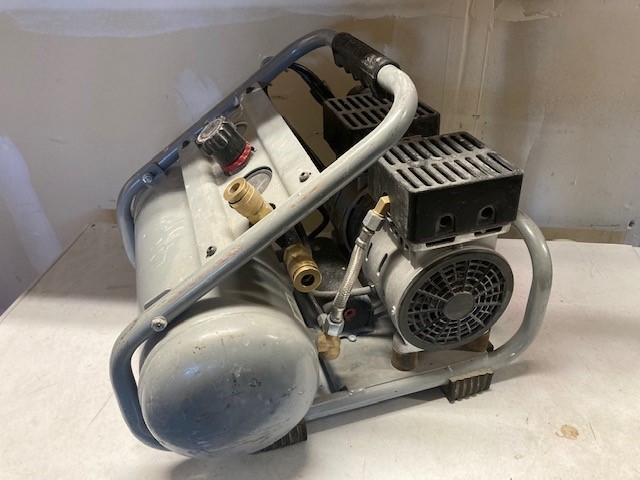

Flash forward to today’s quiet direct drive motor two-stage oil-less air compressor, and it is my goto on the go. Most of the tools I have, including an air impact, can be run from a small compressor for a short period. The lightweight all-in-one carrying frame is mobile.

Holding a conversation with it running next to you is not a problem, even with my hearing.

I have a single-stage oil-lubricated compressor at home. The added initial cost will pay off with trouble-free reliability, With an oil-less compressor, the cost would be approximately 20% less, and the decibels would be too loud to store it in my attached garage.

What are some pros and cons of oil-free air compressors?

5 Pros of an oil-less air compressor

- lower maintenance to the pump.

- fewer parts equal lower price.

- smaller footprint

- less energy consumption

- weight is less than that of equal capacity

5 cons of an oil-less air compressor

- The noise level of this type of compressor is louder at higher pressures.

- dirty environments are catastrophic on oil-less compressors.

- the duty cycle on these compressors is normally much lower.r

- oil-less air compressors run hotter.

- oil-less air compressors do not last as long.

How Does an oil-less Air Compressor Work?

Both types of compressors function much like your car’s engine,

Only without a spark plug and an exhaust stroke. The piston is pulled down, drawing in the fresh air, then is driven up, increasing the pressure. The main difference is the oil-less compressor uses permanently sealed bearings and synthetic gel lubricants.

The oil-less system doesn’t have an oil reservoir Eliminating oils from passing the pistons’ rings and into the compressed air system.

Are Oil-less Air Compressors Better?

To answer this question, let us take a look at a comparison between two compressors on the market manufactured by the same company. Here you see a chart with a side-by-side comparison.

Please take note that the side-by-side comparison is not answering the question entirely.

| oil- free compressor | oil lubricated | |

| Warranty | 2 years | 2 years |

| tank size | 27 Gal | 30Gal |

| decibels(out side) | 80Db | 78Db |

| max pressure | 200 psi | 175 psi |

| horse power | 1.7hp | 2.0 hp |

| cfm @ 40psi | 5.1 cfm | 6.2 cfm |

| cfm @ 90psi | 6.8 cfm | 7.7 cfm |

| amp rating | 15 | 15 |

| weight | 101 | 152 |

| cost at time of article (both from same store) | $399 | $499 |

| saftey data sheet needed | no sheet needed | yes sheet needed |

At first glance of these two similar performing compressors the one hundred dollar cost of the oil lubricated compressor sticks out, the oil-less is only 2 decibels louder, one-half CFM, at 90 psi less than the competitor and lacks only point three horse power.

The biggest concern I have About larger oil-less compressors is Duty-Cycle, I have not seen Duty cycle ratings on any paperwork or online in quite some time. “Duty-cycle” is the amount of time the compressor needs to rest and cool compared to the amount of time it runs. an example of this is a 100% duty cycle rated compressor that will not need to shut off to cool it can stay cool and run non-stop, A 75% duty-cycle rated compressor can run for 45 minutes but then needs to cool off for 15 minutes before restarting. in the case of these two compressors, the oil-less has to work much harder when it turns on at 95 psi to get back to 200 psi. both compressors hold about the same volume of air. but the oil-lubricated compressor only has to reach 175 psi, which will equate to shorter run times and a longer life span.

Why Go With an Oil-Free Compressor?

We’ve talked about all of the benefits. Oil-less air compressors are cheaper than their oil-using counterparts. Because the oil-less compressor is smaller and lighter, it is more cost-effective to manufacture. The energy costs are also reduced because there is no need to collect and store oil-laden condensate. both types of compressors have their place, and I own both