Simply put, an air compressor is a ‘grown-up’ bicycle pump. Basically, a gas, electric, or diesel engine-machine converts its power to energy, which it stores as pressurized air within a tank. This compressed air is then used as energy to perform a vast array of applications, for example, putting air into vehicle tires, painting or polishing, and so much more. A machine this useful and powerful isn’t likely to operate quietly.

Are air compressors loud? Yes, the compressors are loud. Air by itself is silent. The compressed air volume comes from the vibration of the air. If you release water from a hose underwater in a pool, it will create waves. Compressed air released into the atmosphere creates sound waves to which the ear and brain react. These incredible ‘low bass sounds strike the body in offensiveness compared to that of a shock wave coming from something that has exploded.

As this air is depleted, the tank will lose the built-up pressure to its lowest level at the point where the process begins again. There are a few different varieties of air compressors and a multitude of sizes available, each with its own purpose. Some are louder than others.

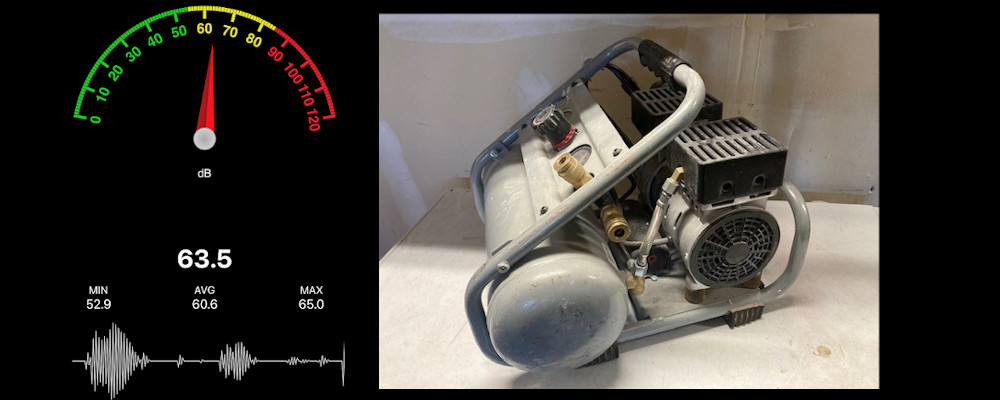

Most Phones can down load an APP to measure The Decibels on your compressor in your Shop.

Just How Loud Is an Air Compressor?

Well, this can vary. Ideally, you want to buy a quiet air compressor below 80 dB as anything over 80 dB is harmful to the human ear. A tip for quieting a loud unit is to distance between you and the machine, particularly walls. Putting it in another room or even better outside by attaching a long air hose can decrease the noise level as much as 25%.

The air compressor models with decibels under 80 deem the designation of quiet or silent. But for a brand to be able to call itself the ‘best quiet air compressor’ if its decibel level is below 60.

What Is A Reasonable Level Of Noise In Decibels For The Compressor? You Choose.

When choosing an air compressor, it’s important to select an option that won’t be harmful to your hearing. In order to do that, you need to understand decibels and what would constitute a reasonable noise level. To get a general idea of decibels in their environment, let’s check out some examples out:

- 30 dB – Empty living room

- 30 -40 dB – Dishwasher

- 50-60 dB – Normal Conversation

- 85 dB – Lawnmower cycling

- 95-500 dB – Electric Drill

- 100dB- Typical person shouting

- 120dB – Loud event

- 130dB – Jet engine cycling

Decibels are logarithmic measures of two waves’ relative power. The most common standard reference, for which there are a few, in dB SPL, which specifies 0 dB, is the average human hearing threshold. The human perception for loudness not being linear allows that decibels are ideal for sound measurement.

Each increase of 10 dB increases signal power incrementally by 10, meaning that 80 dB for which is ideally where the human ear should maintain, is 1000x stronger than a signal of 50 dB.

But the 80 dB won’t be heard as being 1000x louder than the 50 dB sound, making decibels more accurate for describing how people experience the sounds as they hear them. The maximum that a human ear is capable of processing is 200 dB.

So, relatively speaking, typical air compressors which range in loudness from 70 to 90 dB can be considered noisy as far as a person’s interpretation. Generally, these average, loud air compressors might be the ‘cheaper’ varieties. It is possible to select quieter versions. Still, these will be more expensive as they are also considered more sophisticated.

Where Does the Air Compressor Noise Come From?

The ‘cheapest’ loud typical variety of air compressor noise is from the ‘hammer’ of the intake of air while it goes through compression. In essence, a hammer or a piston is technically squashing the air in a tube, placing it under pressure.

A great many units are of the two-stage variety, meaning that the air compresses once, and then it gets piped to a second cylinder. There it gets squashed once again. After the air has gone through these processes, it is taken to a big tank hooked to the compressor. These constitute a large motor and multiple parts and valves in their construction.

For a much quieter option, the compressor uses screws to compress air gradually while it goes through the compressor. These are not only ‘silent,’ but they also offer energy efficiency, higher output, and a more substantial price point than the conventional compressors, but they are also less common than the traditional options.

Tips On Selecting The Right Air Compressor

An air compressor is a diverse tool that compresses air with high pressure for a variety of different purposes. They have increasing popularity in today’s world based on their being clean, flexible, and safe.

These machines are used in a multitude of industries, from automotive, aircraft, textile, to farming. The basic functionality across the board is similar in its increasing pressure and reducing the level of air despite the variation in types on the market.

However, choosing the one ideal for your specific needs is still a challenging concept. Several factors go into making the best selection:

- Noise – We’ve covered this idea well already. The vast majority of the modes on the market are loud, almost to the point of distraction, with people seeking out quiet alternatives or methods to use with the noisy brands to make them softer.

- Price – While there are, in fact, more peaceful, almost silent options that can practically deem ‘too good to be true.’ They do, though, come at a higher cost with a complicated interface. In using the louder choice, there are techniques you can employ to make them sound more bearable as in merely putting it in an area apart from where you’ll be working with walls separating the two spaces or even outside the building.

- Environmental friendliness – A majority of these units take oil as a lubricant for the internal mechanisms for which the fumes serve as contaminants for certain environments resulting in potential damages to products or individual processes.

- Oil-free – varieties decrease this risk. The cost for models that don’t use oil is higher, but in some instances, these are the only option. Oil is still often necessary even for the ‘oil-free’ machines to lubricate the unit, but the inner aspects use a variant sealing option so that no oil goes into the compressor itself. Aside from giving off clean air, these units typically provide the least operating costs because the parts need changing less often.

- Energy efficiency – A big concern, particularly in today’s society, is energy efficiency, which is a concept that should be taken into consideration in the purchase of an air compressor. If you know, you’ll be involved in a long project. The most energy-efficient model is a wise investment.

- Portability – The ability to easily move the unit is essential for those who may travel between different locations. This makes a small, lightweight air compressor a good option as they will still provide energy only in a compact unit.

These are not going to offer the same power that you’ll find in a more extensive system, but they are ideal when you perform small projects. Some of these are capable of plugging into the vehicle power adapter to fuel a tire inflating tool or that for airbrush painting.

Making the Final Decision

Deciding on cost, you don’t want to buy the cheapest on the market because typically you get what you pay for. It’s not necessary to buy the most expensive, either. The ideal way to select from the models in the category that you feel will best meet your needs is to research each brand history, read reviews from past customers, and look at the website where there will likely be testimonials.

When you find one you’re interested in, look for a mid-range price point that offers the features and capabilities you require. You should expect a sufficient lifespan from a model of this sort.

Which Air Compressors Are More Energy Efficient?

Variable vs. a Fixed Speed

Using a variable speed variety can make a difference regarding efficiency. The VSD or Variable-Speed driven compressor saves not only energy but money because it boasts the capability of increased or decreased output as you demand. With fixed comparably, the motor functions always at the same rate, which is okay if the system is in use. But once the unit begins to slow, the motor goes strong until it reaches a full stop wasting energy throughout the cool down with the compressor running even though there is no generation of power.

Natural Gas

Natural gas is a good alternative in certain settings, including industrial for applications like power tools. These are more efficient as compared to diesel or electricity even on partial load and offer the best heat recovery capacity over that of electric versions. For anyone interested in considerable energy savings and efficiency, this is a great resource.

Types Of Air Compressors

Air compressors are incredibly versatile pieces of equipment that you can see in a number of different scenarios. There is a broad spectrum of models with a wide range of sizes, each offering their own abilities and all of them having a potential downside of noise. But those who use them attest that the benefits they boast far outweigh any potential disadvantages.

There are two types of internal mechanics:

- dynamic displacement

- positive displacement

There are four types of air compressors among the most common on the market:

- rotary screw

- reciprocating

- axial

- centrifugal

Let’s check all of these out a little further.

- Positive Displacement Air Compressors

These produce power by displacing air. There are a variety of models in this category, all of which work using the same concept. There is a cavity existing within the machine where the atmospheric air is stored and becomes compressed in an effort to increase pressure and energy.

- Rotary screw air compressors have two internal rotors, which have the capacity for continuous use.

- Reciprocating air compressors use the assistance of a piston in the cylinder. These don’t have the capacity for use on a continuous basis.

2. Dynamic Air Compressors

In producing its necessary power using a rapidly rotating blade to intake air, a dynamic air compressor will generate pressure in the tank aiding in storing kinetic energy as static energy within the container.

Centrifugal air compressors can produce a massive amount of energy via a process involving multi-stage compression. These are common in larger manufacturing industries.

Axial air compressors are among the most expensive. They provide a lot of power and excellent efficiency, which is beneficial for use in the ships and airplane industry where they’re most prevalent.

Which of These Is Best for Home?

The most common of these types is the reciprocating piston, which is especially beneficial in the home setting or a small shop environment. As a rule, a majority of air compressors useful in the home atmosphere are portable to the point of moving on wheels or even carrying from place to place.

For those who have a small studio or workshop where pneumatic tools are implemented, it’s beneficial to incorporate a bigger stationary tank as a better air source in this situation. For this particular model, there are also options for model stages one or two for which the two-stage gives an air supply that is more powerful with a higher PSIG rating.

Benefits Of Using A Portable Air Compressor

Air compressors come in a variety of sizes, models, brands, and or a multitude of uses. One which has unique practicality is the portable air compressor due to its functionality and convenience.

They are easy to transport if you need to move locations frequently, plus they comprise a majority of the same features as that of their larger counterparts. You don’t realize how useful these might be unless you find yourself incapacitated as with a tire starting to go flat out in the middle of nowhere.

The wide range of uses for a portable air compressor include:

- Craftspeople using them to power up their air-powered tools in order to perform their day-to-day job functions. The size allows comfort when working on specific projects over an extended period of time throughout the course of the day.

- Hobby enthusiasts – are employing them for airbrushing projects for arts and crafts.

- DIY home improvers – more on this later!

The thing that sets these compressors apart from every other option on the market is the fact that they easily stored, and filling them is cost-effective.

A loud compressor on the job front is burdensome when trying to communicate with colleagues or concentrate on your work. Typically, on an industrial site, there are not many places for equipment storage, making a compact unit perfect for this type of atmosphere. And the amount of use that the system will endure brings the need for frequent refilling, making the low-cost factor of a portable unit appealing for the trade industry.

The Best Air Compressor for DIY Projects at Home

DIY is fun and prevalent on the home front. Homeowners always find a reason why something needs to be taken apart and put back together. An air compressor is a great tool to have around if you like to work on the house.

There is a wide array of air tools that you can use in combination with the portable air compressor allowing for complete versatility so that jobs that need completing for the typical homeowner can be accomplished in no time.

- Cleanup: If you attach a blower tool when performing DIY projects around the house, it makes fast work of cleaning the sawdust off of the flooring.

- Painting: Thee paint sprayer tool allows for easy color changes on bicycles, go-karts, or any items where your small one wants a change.

- Nailing: The air finish nailer helps put the baseboards or crown molding where it belongs.

- Pumping air: Typically, a smaller unit is all that you’ll need if your purpose is strictly for the purpose of ‘filling’ as with inflating various tires, pumping sports gear, or filling up an inflatable air mattress.

The project that you intend to work on and the tools that you want to implement are going to help you decide on the style and the type of unit for which you should invest.

The best thing for the homeowner is you can do everything with the only effort being the need to learn the unit. The suggestion if you live in a tiny apartment or a small space of that sort is to invest in a ‘pancake’ system. This compressor is especially diminutive when you live in a minimal space, but it is merely for lighter jobs.

For that DIY enthusiast who will never find an end to their to-do list, you will need a vast array of air tools, and with that comes a unit that has plenty of capacity to operate them efficiently, and some of these tools require more power than others. There’s a multitude of options that are great for home – do some online homework to find the one that suits your needs.

Wear Protective Earwear

When you’re shopping, if the noise factor is important to you, do a little digging to find out the dB level of the model you are looking at. And, if you end up with a more powerful and louder unit than you expected, invest in a pair of noise-canceling headphones to protect your ears. Something like these noise-protecting earmuffs will go a long way in making sure you aren’t harming your ears.

Loud or Not – Air Compressors Are a Great Tool to Have

At the end of the day, an air compressor is the ‘tool’ of all tools. When you make the investment in the unit that is meant for you, you’ll question why you didn’t make that leap a long time ago. It’s truly astonishing how practical, pragmatic, and downright awesome an air tool can genuinely be.